Hit & Miss engines were made by a multitude of engine

manufacturers during their peak usage which was from approximately

1910 through the early 1930's when they began to be replaced by

more modern designs. Some of the largest engine supplier's

were Stover, Hercules, International Harvester,

McCormick Deering, John Deere and

Fairbanks Morse.

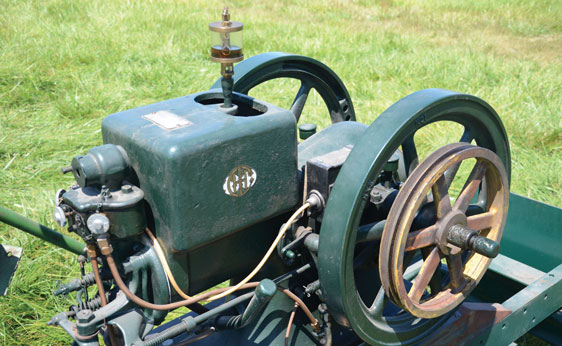

A Hit & Miss engine is a type of flywheel engine. A flywheel engine

is an engine that has a large flywheel or set of flywheels

connected to the crankshaft. The flywheels maintain

engine speed during engine cycles that do not

produce driving mechanical forces.

The flywheels store energy on the combustion

stroke and supply the stored energy to the mechanical load on the

other three strokes of the piston. When these engines were

designed technology was not nearly as advanced as

today and all parts were made very large.

The flywheels store energy on the combustion

stroke and supply the stored energy to the mechanical load on the

other three strokes of the piston. When these engines were

designed technology was not nearly as advanced as

today and all parts were made very large.

A typical 6 horsepower engine weighs approximately 1000 pounds.

Typically, the engine material was mainly cast iron and all

significant engine parts cast from it. Small functional

pieces are made of steel and machined to perform

their function.

Hit & Miss engines were made to produce power outputs from 1

through approximately 100 horsepower. These engines are

slow speed and typically ran from 250 revolutions

per minute (rpm) for large horsepower engines

to 600 rpm for small horsepower engines.

They were used to power water pumps for

cultivation, saws for cutting wood, generators for electricity in rural

areas, running farm equipment and many other applications. Some

were mounted on cement mixers. These engines also ran some

of the early washing machines. They were used as a

labor saving device on farms, and allowed the

farmer to accomplish much more than he

was previously able to do.

They were used to power water pumps for

cultivation, saws for cutting wood, generators for electricity in rural

areas, running farm equipment and many other applications. Some

were mounted on cement mixers. These engines also ran some

of the early washing machines. They were used as a

labor saving device on farms, and allowed the

farmer to accomplish much more than he

was previously able to do.

The engine was typically belted to the device being powered by a wide

flat belt, typically from 2 - 6 inches wide. The flat belt is driven

by a pulley on the engine that attached either to a flywheel

or to the crankshaft. The pulley is specially made in

that its circumference is slightly tapered from the

middle to each edge, like an over inflated car

car tire, so that the middle of the pulley

is a slightly larger diameter. This

keeps the design flat belt in

the center of the pulley.

Although thousands of out of use flywheel engines

were scrapped in the iron and steel drives of World War II, many

survived to be restored to working order by enthusiasts.

However in recent years engines with original paint

have become more desirable to many collectors

than repainted engines. Numerous preserved

Hit & Miss engines may be seen in action

at shows dedicated to antique engines.

Although thousands of out of use flywheel engines

were scrapped in the iron and steel drives of World War II, many

survived to be restored to working order by enthusiasts.

However in recent years engines with original paint

have become more desirable to many collectors

than repainted engines. Numerous preserved

Hit & Miss engines may be seen in action

at shows dedicated to antique engines.

Except for some of the big engines still in use in the oil fields, most have

become collectors items. Nothing today sounds quite like a Hit &

Miss popping along at a show. Let's hope these relics of the

past will be here for future generations to enjoy.

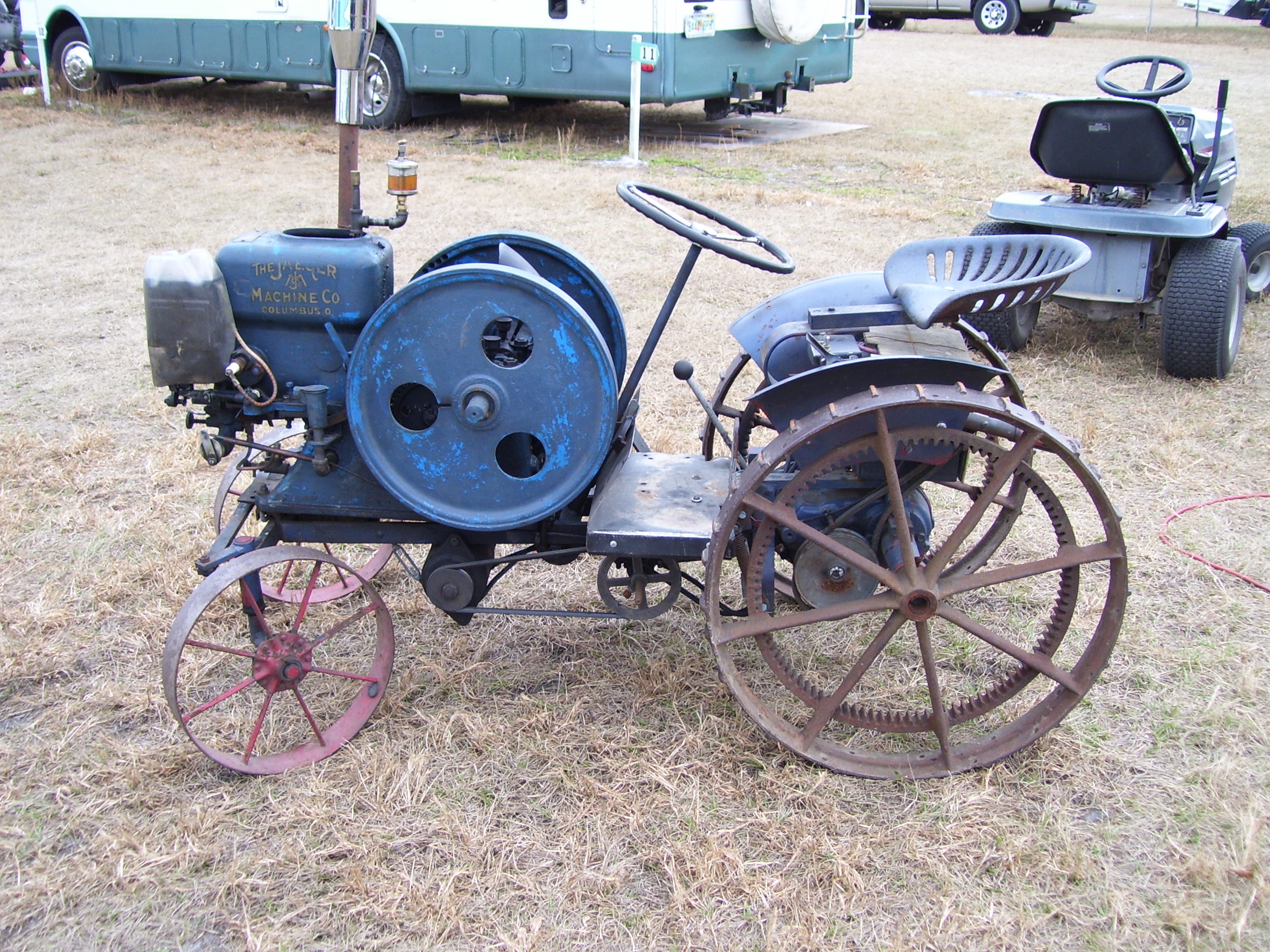

Examples of Hit & Miss Engines in Small Tractors

*

In Progress . . . . .

A TTG Design/Build Hit & Miss Tractor...

View Here

The Tractor Guy's are

members of the

31 Kent Cornwall Rd, Kent, Ct.

More Information

TTG Home Page

TTG Home Page

© 2011 ~ 2022

site was designed built and is maintained by

thetractorguysct.com all rights reserved